Industrial Automation Company in Munich

Introduction

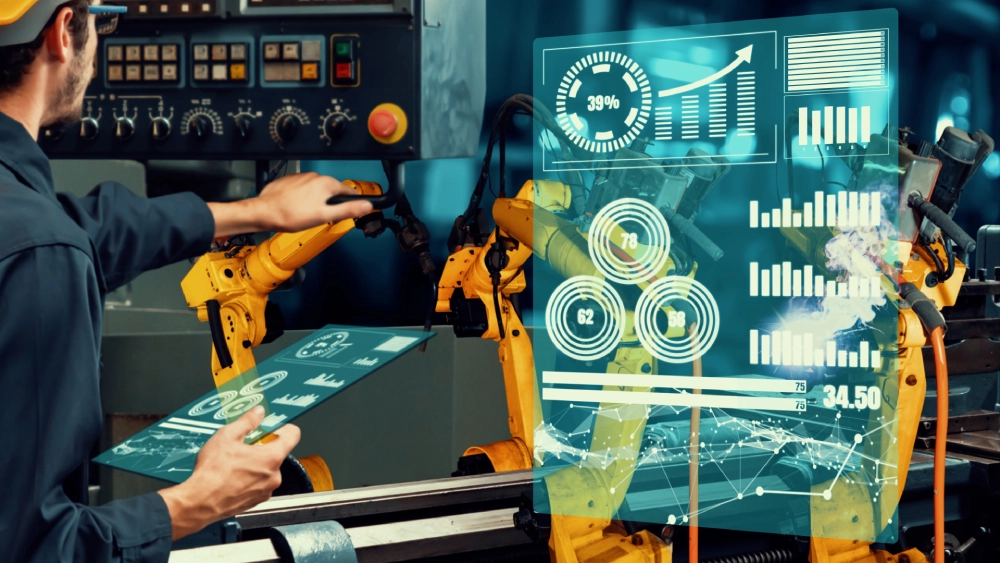

Munich’s advanced industrial ecosystem thrives on innovation — and Arcitech is driving that progress as a leading industrial automation company in Munich. We help manufacturers modernize production, reduce downtime, and enhance efficiency using AI and IoT technologies.

Our award-winning engineers combine AI, robotics, and machine learning to design next-generation automation systems.

Why Choose Us in Munich

We are a trusted name in industrial automation across Bavaria, delivering intelligent systems that boost productivity and reduce operational costs.

Why Arcitech:

• AI-powered predictive maintenance.

• NLP-driven process control for smarter operations.

• IoT integration for real-time monitoring.

• Continuous optimization for peak output.

Our Expertise

Machine Learning Development Services

Predictive models for proactive performance.

Natural Language Processing (NLP) Development

Smart control through human-like interaction.

SCADA & PLC Systems

Real-time visibility and control.

Industrial Robotics Integration

Automation that enhances precision and safety.

Our Process

Assessment & Strategy

Evaluate current operations and define KPIs.

Design & Engineering

Build modular, scalable automation systems.

Deployment & Testing

Ensure reliability, safety, and efficiency.

Support & Optimization

Maintain continuous improvement post-launch.

Technologies We Use

FAQs

1. What types of industrial automation solutions do you offer in Munich?

Arcitech provides end-to-end automation solutions, including machine learning models, NLP-powered control systems, SCADA and PLC integration, industrial robotics, IoT-connected monitoring, and predictive maintenance systems. Each solution is engineered to enhance efficiency, reliability, and performance.

2. Can industrial automation be integrated with our existing factory systems?

Yes. Our engineers specialize in seamless integration with legacy equipment, PLCs, SCADA systems, ERP platforms, and IoT devices. We ensure new automation layers function smoothly with your existing infrastructure—without production disruptions.

3. How long does an industrial automation project typically take?

Timelines depend on system complexity, data readiness, and deployment scale. On average:

• Small automation upgrades: 4–8 weeks

• Full-scale industrial automation implementations: 3–6 months

After an initial assessment, we provide a detailed roadmap with clear milestones.

4. Do you provide ongoing maintenance and optimization for automation systems?

Absolutely. Arcitech offers continuous support, real-time monitoring, performance optimization, predictive maintenance updates, and system enhancements. We ensure your automation environment evolves with production demands and remains future-ready.